doner kebab machine

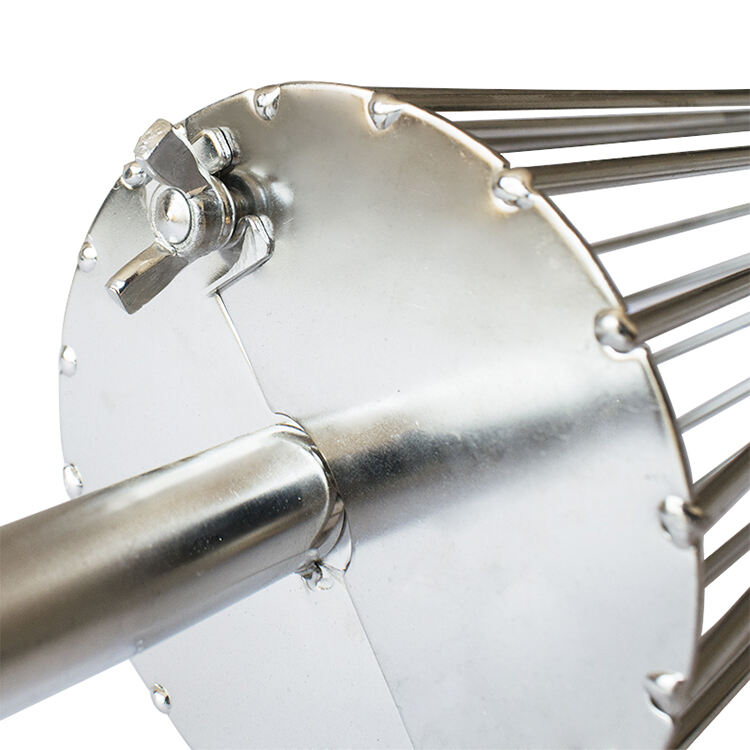

The doner kebab machine is a specialized piece of commercial kitchen equipment designed to cook and showcase vertical rotating meat spits. This innovative cooking system features a vertical rotisserie mechanism that slowly rotates seasoned meat stacks against powerful heating elements, ensuring even cooking and perfect browning. The machine typically incorporates adjustable temperature controls, allowing operators to maintain precise cooking temperatures between 150-300°C. Most modern units come equipped with robust motors that can support meat loads ranging from 10 to 60 kg, making them suitable for various establishment sizes. The cooking process involves a combination of radiant and convection heating, with infrared elements positioned strategically to ensure consistent heat distribution. Safety features include emergency stop buttons, overheating protection, and stable base construction. The machine's design typically includes a drip tray for collecting excess fat, maintaining cleanliness and safety during operation. Advanced models often feature energy-efficient heating elements and programmable controls for optimal performance and resource management. The equipment's versatile nature allows it to accommodate different meat types, including lamb, chicken, beef, or mixed meat combinations, making it an essential tool for Mediterranean and Middle Eastern restaurants, food trucks, and casual dining establishments.